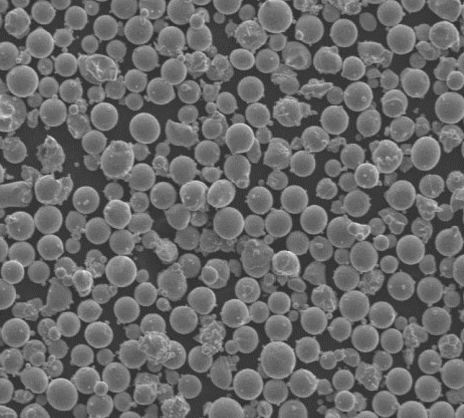

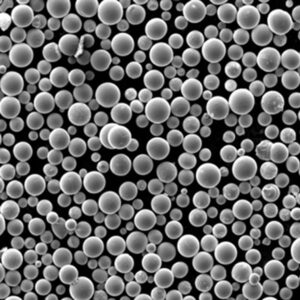

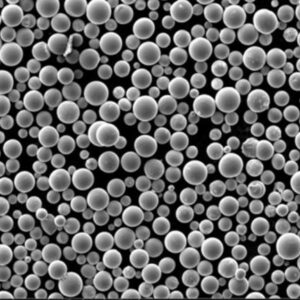

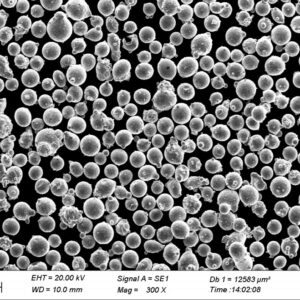

Nickel-based K403 Powder

K403 powder is a highly versatile and advanced material that finds widespread application in various industries. It is a finely ground substance that consists of carefully selected components, making it ideal for a multitude of uses. The unique chemical composition of K403 powder allows it to exhibit exceptional properties, making it highly sought after in industrial processes.

Fast Delivery

High sphericity

High Quality

Small MOQ

Share This Product

Product Description

2. Properties of K403 Powder

K403 powder boasts several remarkable properties that set it apart from traditional materials. Its fine particle size and uniform distribution contribute to its excellent flowability, ensuring consistent performance in diverse applications. Furthermore, K403 powder exhibits exceptional thermal stability, chemical resistance, and mechanical strength, making it suitable for use in demanding environments.

3. Applications of K403 Powder

The applications of K403 powder are vast and diverse, making it a valuable asset across multiple industries. Let’s explore some of the prominent applications where K403 powder excels:

3.1 Automotive Industry

In the automotive industry, K403 powder is widely used for manufacturing lightweight and high-strength components. It enables the production of parts that offer superior mechanical properties, such as enhanced durability and reduced weight. K403 powder finds application in the fabrication of engine components, transmission systems, and structural elements, contributing to improved fuel efficiency and overall performance.

3.2 Aerospace Sector

The aerospace sector demands materials that can withstand extreme conditions while minimizing weight. K403 powder fulfills these requirements, making it a preferred choice for aerospace manufacturers. It finds application in the production of aircraft components, such as turbine blades, structural parts, and heat shields. The exceptional strength-to-weight ratio of K403 powder enhances fuel efficiency and ensures reliable performance in challenging environments.

3.3 Medical Equipment Manufacturing

In the field of medical equipment manufacturing, K403 powder plays a vital role in producing high-quality devices and implants. Its biocompatibility and corrosion resistance make it an excellent choice for applications such as orthopedic implants, dental prosthetics, and surgical instruments. The use of K403 powder ensures the longevity and reliability of medical devices, contributing to improved patient outcomes.

3.4 Energy Generation and Storage

K403 powder finds application in the energy sector, particularly in the production of batteries and fuel cells. Its exceptional conductivity and chemical stability make it an ideal material for electrode manufacturing. By using K403 powder, energy storage devices can achieve higher energy densities, improved performance, and extended lifespan.

4. Advantages of Using K403 Powder

The utilization of K403 powder in industrial processes offers numerous advantages that contribute to operational efficiency and product quality. Some key advantages of using K403 powder include:

- Enhanced mechanical properties: K403 powder enables the production of components with superior strength, durability, and dimensional stability.

- Lightweight design: The low density of K403 powder allows for the creation of lightweight products without compromising performance.

- Chemical resistance: K403 powder exhibits excellent resistance to chemicals, making it suitable for applications involving corrosive environments.

- Thermal stability: The high thermal stability of K403 powder ensures consistent performance even in high-temperature environments.

- Improved energy efficiency: By utilizing K403 powder, industries can enhance energy efficiency, leading to reduced costs and environmental impact.

5. How to Use K403 Powder Effectively

To maximize the benefits of K403 powder in your industrial processes, it is crucial to use it effectively. Here are some guidelines for using K403 powder:

- Proper storage: Store K403 powder in a dry and controlled environment to maintain its quality and prevent contamination.

- Accurate dosage: Follow the recommended dosage guidelines to achieve the desired performance and avoid wastage.

- Mixing considerations: Ensure thorough mixing of K403 powder with other materials to attain uniform distribution and consistency.

- Equipment compatibility: Use equipment that is compatible with K403 powder to prevent damage and ensure efficient processing.

6. Safety Considerations when Handling K403 Powder

While K403 powder offers numerous benefits, it is important to prioritize safety when handling this substance. Follow these safety considerations to mitigate potential risks:

- Personal protective equipment: Wear appropriate protective gear, including gloves, goggles, and respiratory masks, when handling K403 powder.

- Adequate ventilation: Ensure proper ventilation in work areas to minimize exposure to airborne particles.

- Training and awareness: Educate employees about the safe handling and storage of K403 powder to prevent accidents and injuries.

- Emergency preparedness: Have a well-defined plan in place to handle emergency situations, such as spills or leaks, and provide access to safety showers and eye-wash stations.

7. Future Developments and Innovations

The field of material science is continually evolving, and researchers are constantly exploring new possibilities for enhancing the properties of K403 powder. Future developments may include:

- Improved strength-to-weight ratio

- Enhanced heat resistance

- Expansion of applications in alternative energy sectors

8. Conclusion

K403 powder is a revolutionary material that offers a wide range of applications and benefits across various industries. Its unique properties, including exceptional thermal stability, chemical resistance, and mechanical strength, make it an invaluable resource for optimizing industrial processes. By incorporating K403 powder into your operations, you can achieve enhanced product performance, energy efficiency, and cost savings. Embrace the power of K403 powder and take your business to new heights.

9. FAQs

Q1. Can K403 powder be used in food-related industries? No, K403 powder is not suitable for use in food-related industries as it is not food-grade certified.

Q2. Is K403 powder environmentally friendly? Yes, K403 powder is known for its eco-friendly properties. It is non-toxic and does not contribute to environmental pollution.

Q3. Can K403 powder be recycled? Yes, K403 powder can be recycled and reused in various applications, reducing waste and promoting sustainability.

Q4. What is the shelf life of K403 powder? When stored properly, K403 powder has a long shelf life. However, it is recommended to follow the manufacturer’s guidelines for optimal usage.

Q5. Where can I purchase K403 powder? You can obtain K403 powder from reputable suppliers and distributors specializing in industrial materials.

PREP System

AM Powder

Products Menu

Sent Inquiry

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Related products

-

TC18 Powder : Unlocking the Power of Titanium Carbide

TC18 powder refers to a fine powder composed of titanium…

-

FeCoNiCrMo Powder

FeCoNiCrMo powder is a complex alloy powder consisting of iron…

-

Best IN738 powder for 3D printing in 2023

Inconel 738 powder is a remarkable superalloy that boasts exceptional…

-

Inconel 625 Powder丨Nickel based superalloys

In625 powder is a powdered form of the nickel-chromium alloy…

Applications

How we play a role in the industry

HIP Technology

Hot Isostatic Pressing (HIP) technology works by placing the product in a closed container, filling it with inert gas and sintering or densifying the product at a very high temperature (usually close to the forging temperature of the material) and at a very high pressure (usually 100 – 140 MPa). This allows the product to be sintered or densified.

MIM Technology

MIM products can be complex in shape, precise in size, high in strength and produced automatically in large quantities, and can significantly reduce the complexity and cost of traditional metalworking

SLM Technology

SLM, also known as Selective Laser Melting, is similar in principle to SLS in that a laser is used to melt and solidify metal powder in a specified area, which is then moulded in a layer-by-layer stack.

EBM Technology

Electron beam melting refers to a vacuum melting method in which the kinetic energy of a high speed electron beam stream is converted to heat as a heat source for melting metals under high vacuum. The abbreviation is EBM.

POPULAR SERVICE

Our Professional Services

For Additive Manufacturing

Various Products

Here we provide more than 40 grades of high-quality powders.

3D Printing

SEBM&PREP technology and equipment.

Customization

Accept OEM/ODM

No Risk

Perfect supply chain layout

High Quality

Top sales and quality

Fair Prices

High quality products at reasonable prices

Send Inquiry

Thank you for your interest in our products. If you have any enquiry about quotation or cooperation, please feel free to leave us message by using the following enquiry form. Our sales representative will contact you within 24 hours.

Copyright © 2023 Truer All Rights Reserved